Services

Talk to Us

Talk to a member of our team about

your project and get a quote now.

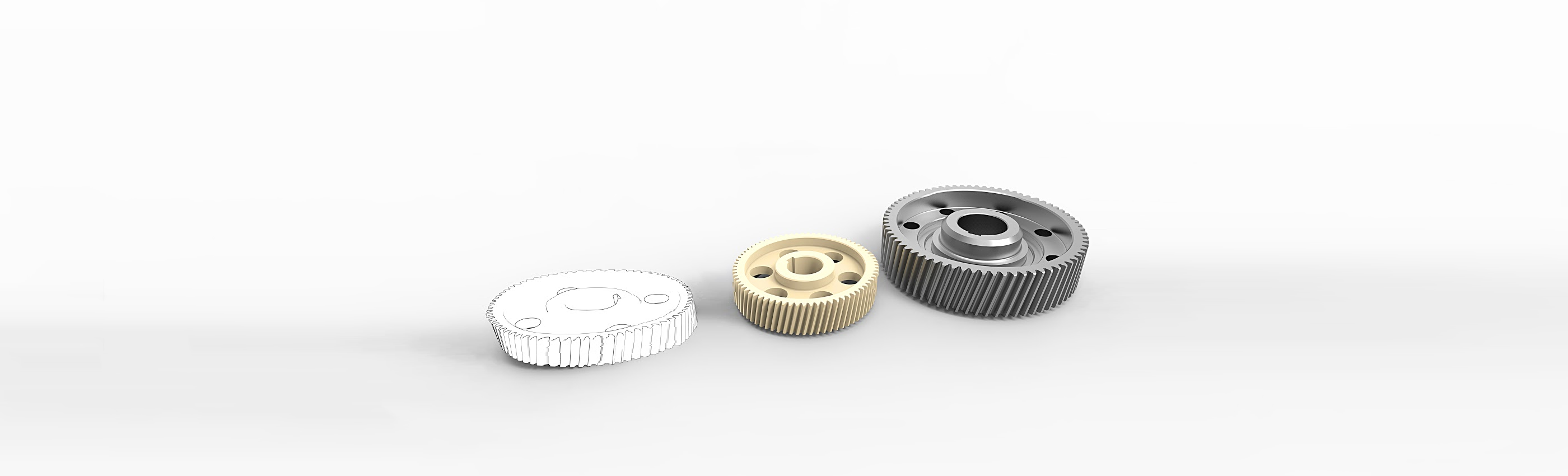

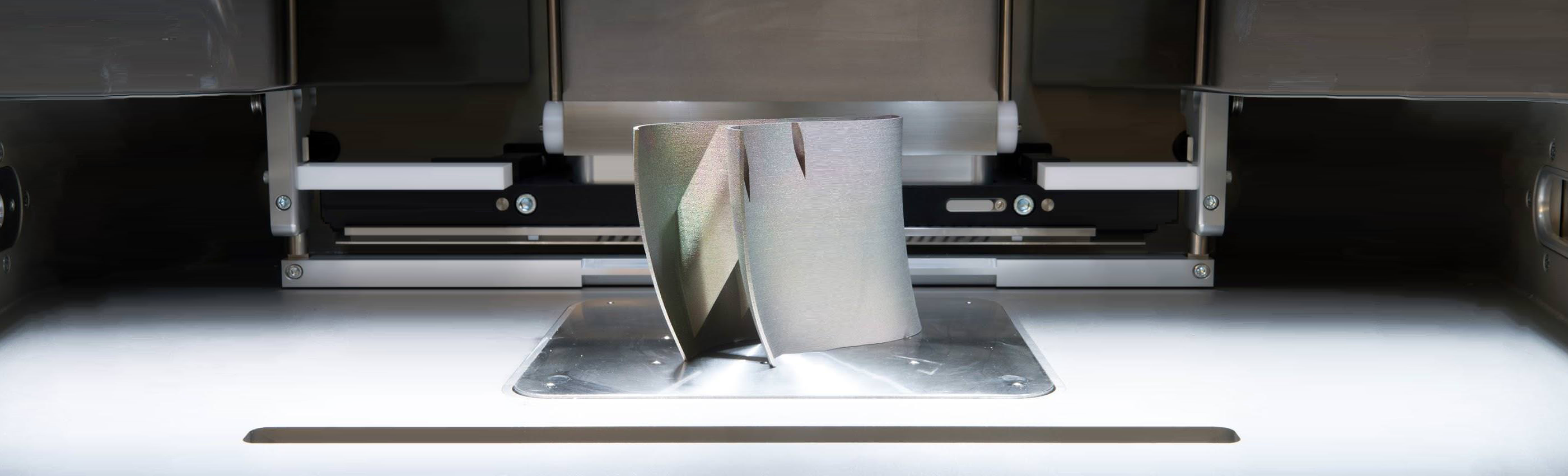

Direct Metal Laser Sintering (DMLS)

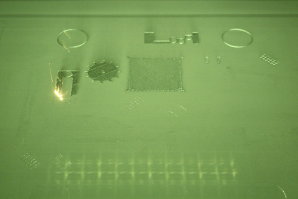

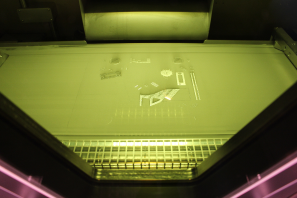

Direct Metal Laser Sintering (DMLS) is an additive manufacturing process melting fine powders to directly build metal components.

Advantages of Direct Metal Laser Sintering (DMLS):

- Powerful additive manufacturing process allowing design driven manufacturing

- Thin wall and hollowing of components

- Pressure tapped components & cooling channels

- Fully dense, high performance materials

- Substantial waste savings over machining

- DMLS offers flexible batch production

- Ideal for one-off prototypes and low volume production

- Typical lead-times 3 – 5 days

- Typical tolerance ±0.04mm

- Typical repeatability 0.02mm

- Minimum wall thickness 0.2mm

- Maximum build size 275 x 275 x 420mm

- Typical surface finish 3-5 Ra before any machining or polishing

3D Systems ProX 200

Material: MS1 / M300 steel

Build Volume: 140x140x100mm

Renishaw AM250

Material: MS1 / M300 steel

Build Volume: 250x250x300mm

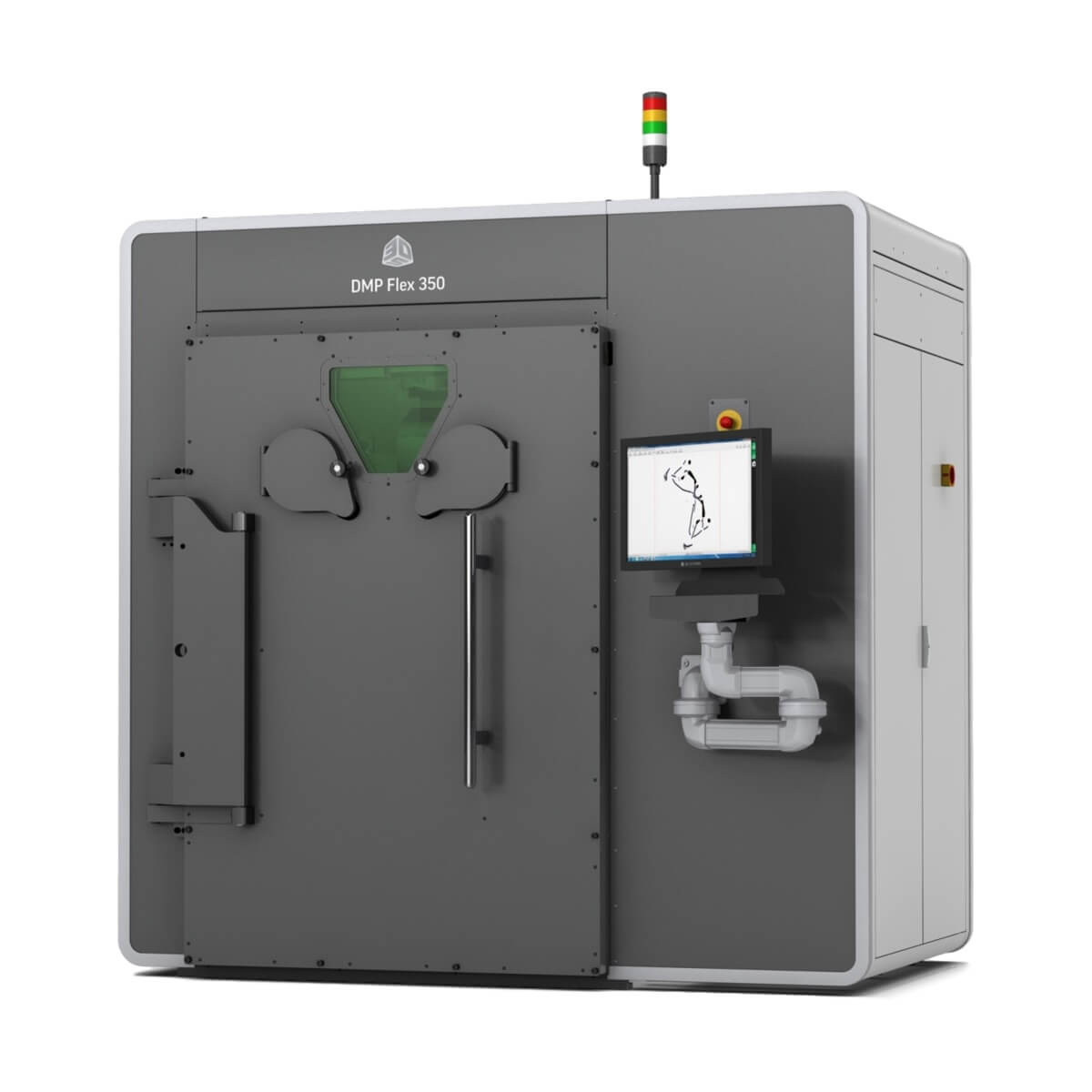

3D Systems DMP Flex 350

Material: Ti64 (Grade 5)

Build Volume: 275x275x420mm